Founder & Tech Lead – Lerix Karya Nusantara

2021 – Present

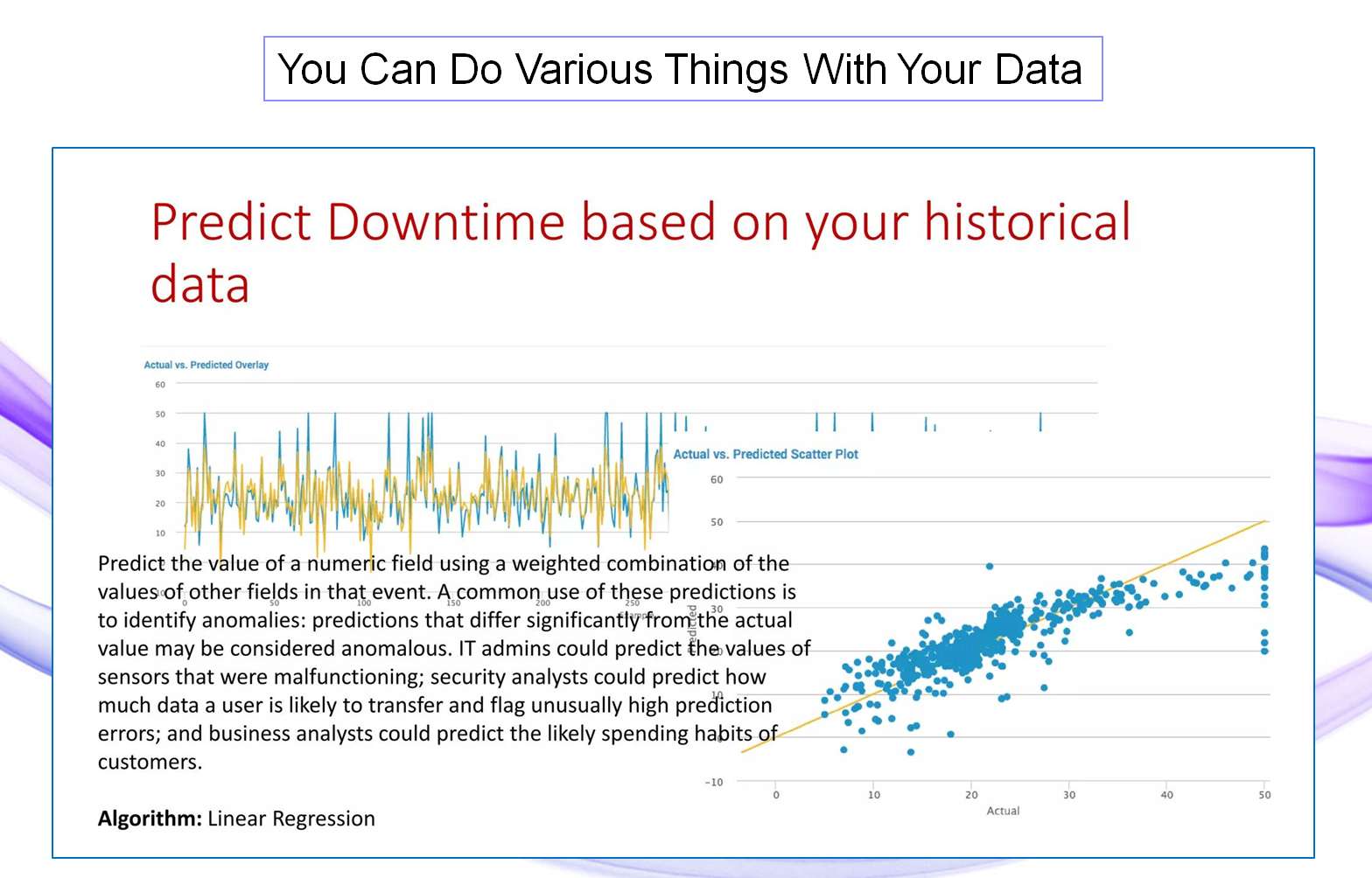

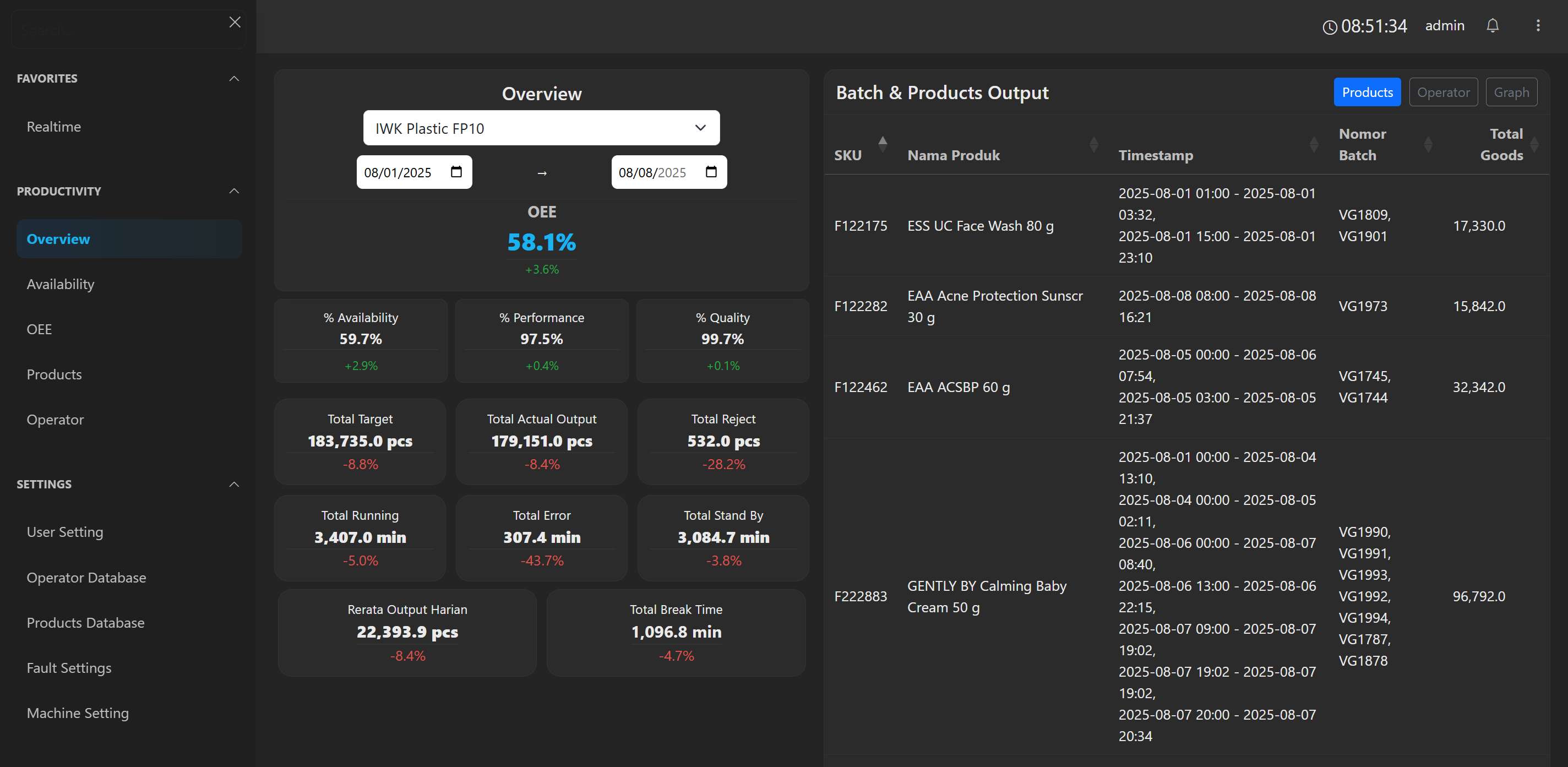

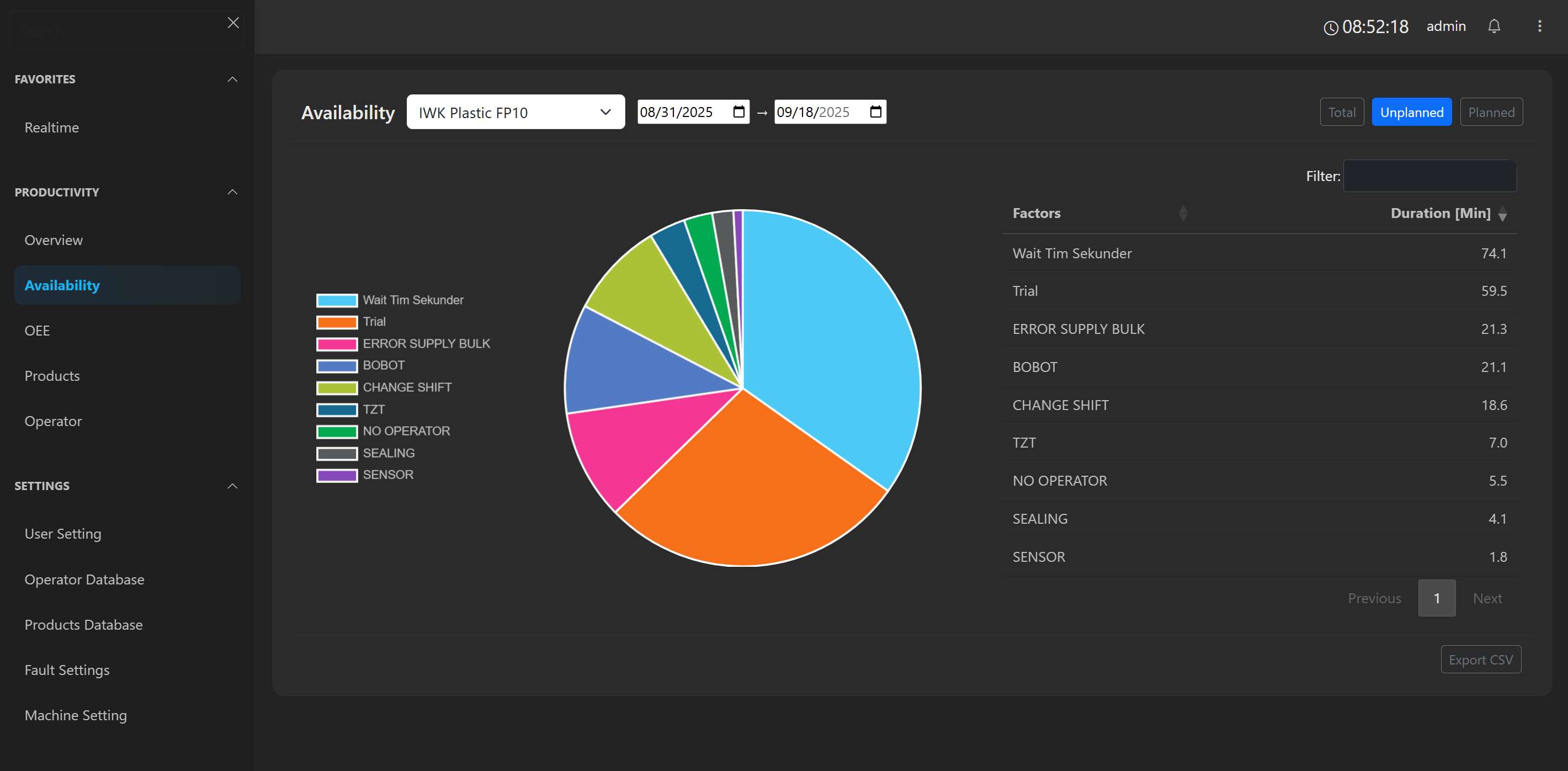

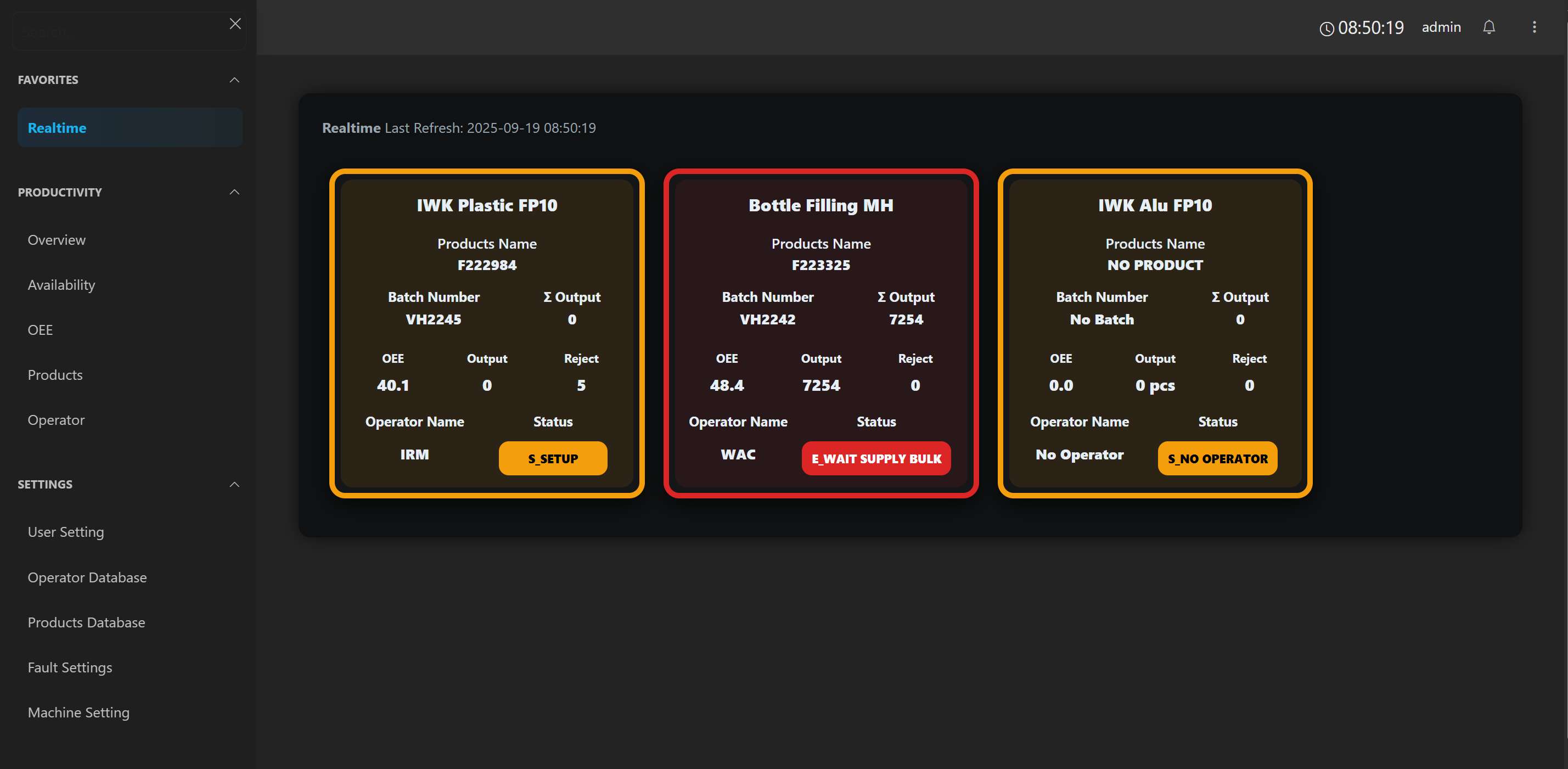

S: Noticed that multiple manufacturing clients struggled with fragmented data collection systems, leading to poor production visibility and delayed decision-making. Manual reporting consumed valuable engineering time and hindered timely executive insights.

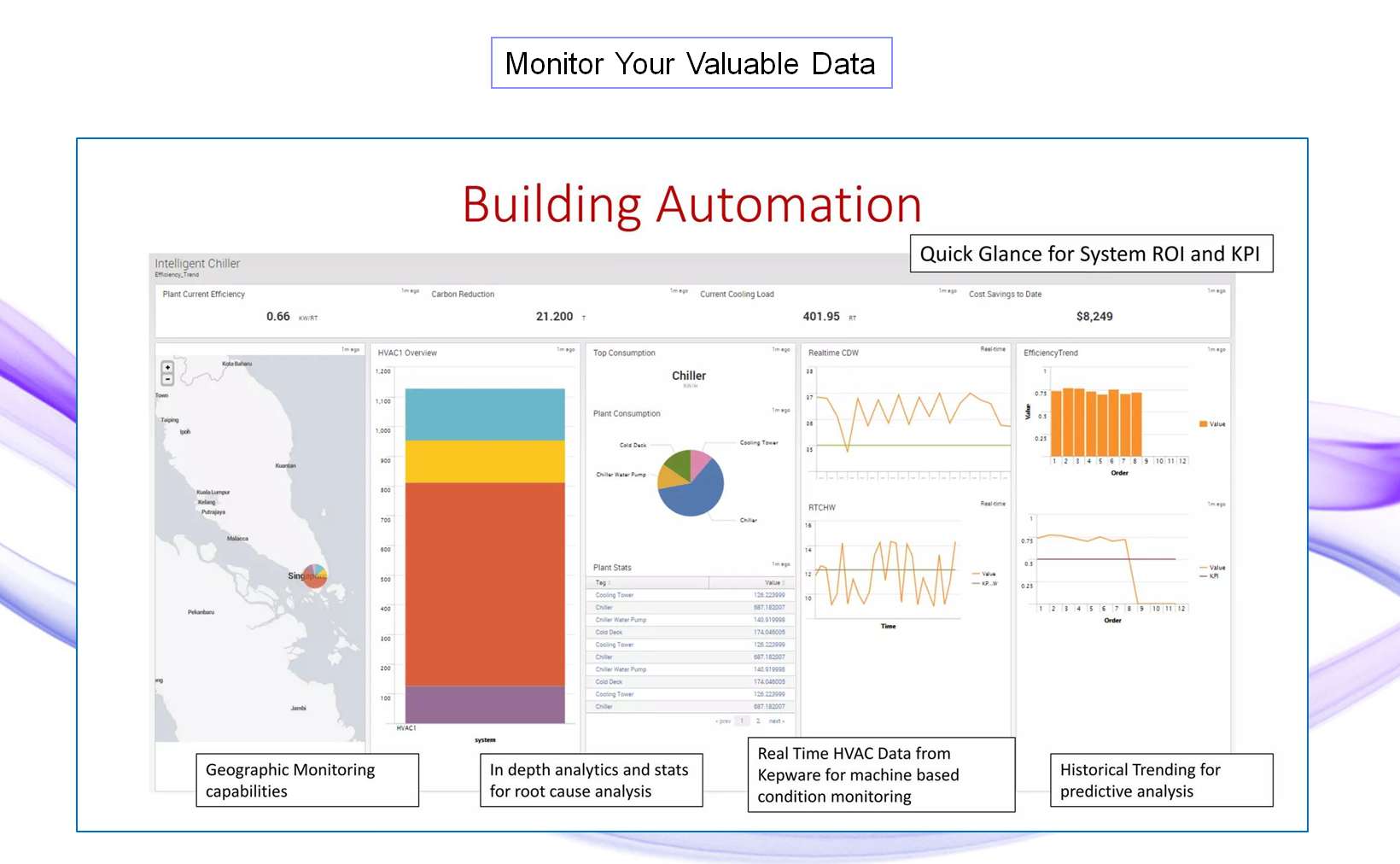

T: Set out to design and deliver a scalable, low-latency industrial data acquisition (DAQ) and OEE platform capable of integrating diverse PLC protocols and delivering real-time analytics across multiple plants.

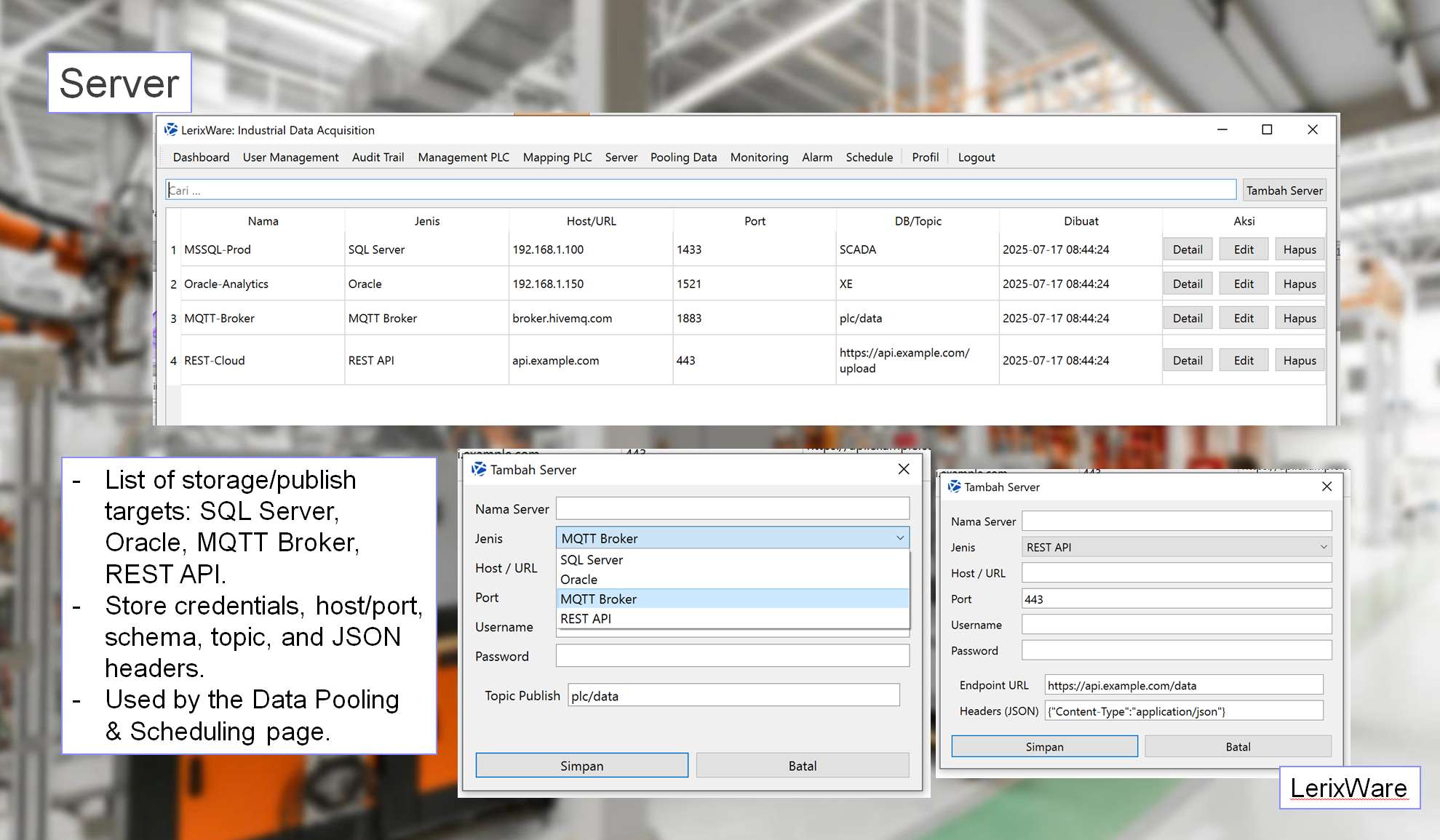

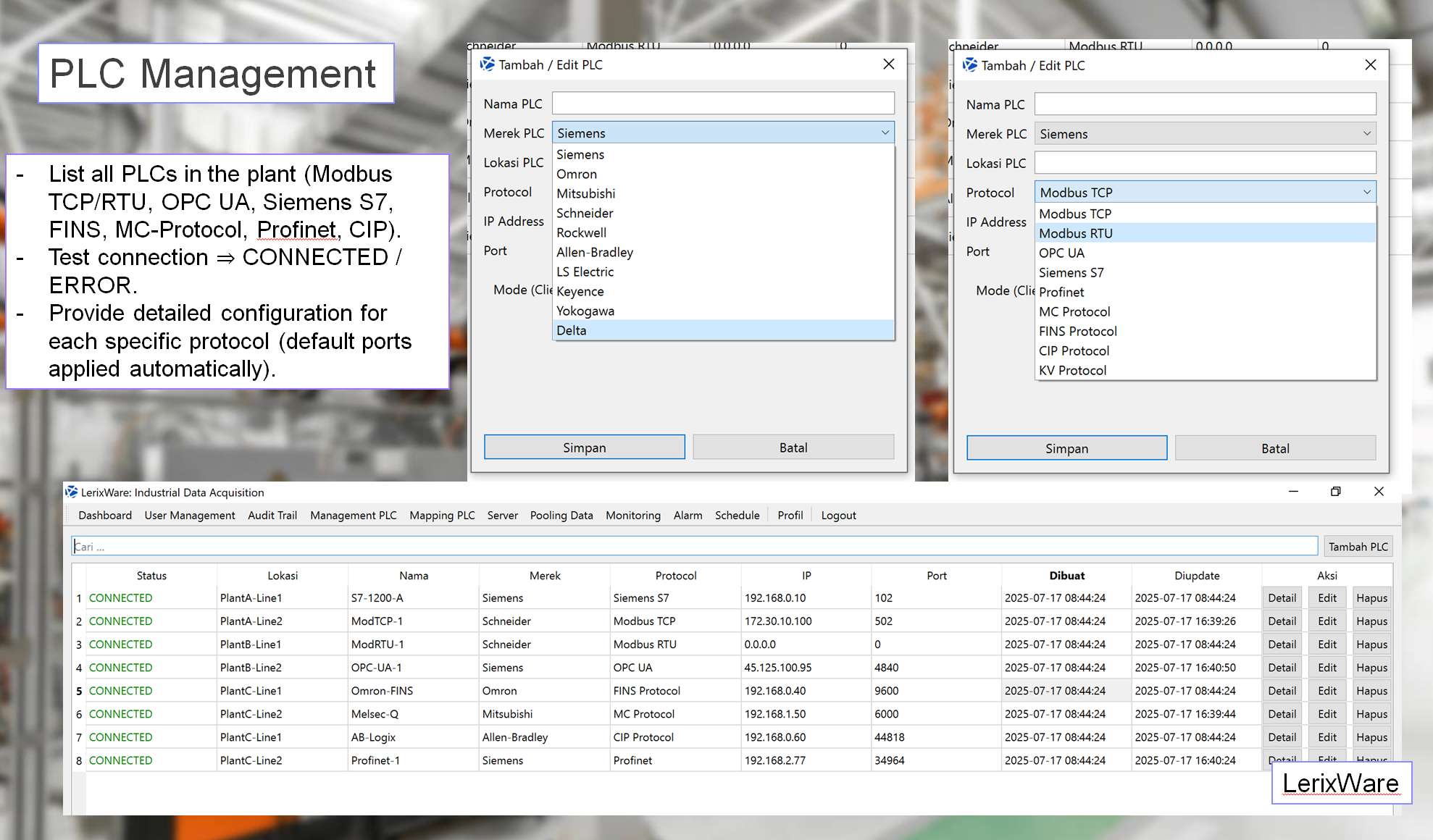

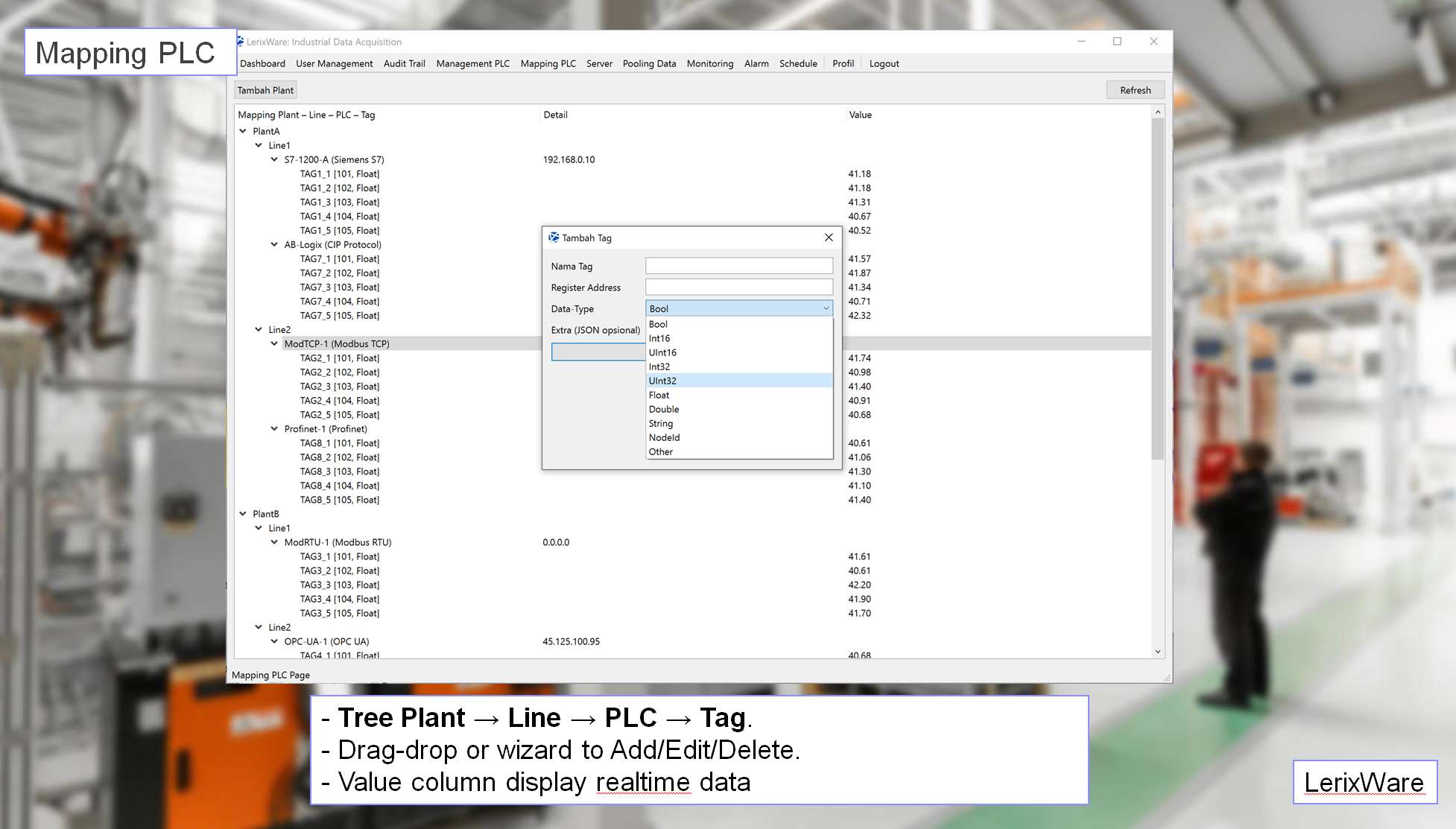

A: Architected a modular DAQ framework supporting Modbus, FINS, MC Protocol, OPC UA, Siemens S7, Profinet, MQTT, and other industrial protocols. Built ETL pipelines for aggregating, cleansing, and transforming shop-floor data. Developed real-time dashboards and automated alerting systems to monitor production KPIs. Implemented CI/CD and infrastructure-as-code for rapid and reliable deployment. Collaborated closely with plant engineers to ensure seamless adoption and usability.

R: Successfully deployed the solution across 11 plants, achieving consistent usage and executive-level adoption. The platform became a central source of truth for production monitoring and decision-making. (Reduced manual reporting time by 50%. Maintained service availability under production loads. Enabled cross-plant performance benchmarking, driving measurable improvements in OEE.)

Software Developer – Food Opera Express

2020 – 2021

S: Rapid growth in delivery and dine‑in orders required better internal tools and a seamless online ordering experience.

T: Build and maintain internal and customer‑facing web apps to support restaurant operations and ordering at scale.

A: Developed menu management, order tracking and payment integration features. Optimised frontend and API performance, reducing page load times and smoothing user journeys.

R: Enabled smoother day‑to‑day operations and a more reliable ordering flow, improving usability and reducing support noise. (Faster page loads and improved UX)

Software Developer – Edulogy

2019 – 2020

S: The learning platform needed engaging features and a backend that could scale with growing cohorts.

T: Design and implement interactive education functionality and a clean API and data model to support it.

A: Delivered quizzes, progress tracking and content management. Designed backend APIs and database architecture for scalable delivery. Improved reliability by reducing crashes and tidying critical paths.

R: Lifted learner engagement and platform stability with clearer progression and fewer interruptions. (Stability and engagement improvements)

IT Support Officer – Four Points by Sheraton Bandung

2018 – 2019

S: Hotel operations depended on reliable network, POS systems and guest Wi‑Fi while meeting Marriott IT standards.

T: Maintain core IT infrastructure, streamline ticket resolution and ensure compliance with brand security policies.

A: Monitored and maintained network and POS systems, optimised helpdesk workflows to remove bottlenecks, and applied required security controls and updates.

R: Reduced downtime across departments and supported smooth guest experiences while passing compliance checks. (Lower downtime and compliant operations)

References & detailed metrics available on request.